Product list產(chǎn)品列表

- GW系列船用齒輪箱GW series Marine gearbox

- 重慶齒輪箱有限責(zé)任公司GV雙機(jī)并車系列齒輪箱

- 重慶齒輪箱有限責(zé)任公司GCH\GCS齒輪箱

- 重慶齒輪箱有限責(zé)任公司GQ/GA齒輪箱

- 重慶齒輪箱有限責(zé)任公司風(fēng)力發(fā)電增速齒輪箱

- 重慶齒輪箱有限責(zé)任公司偏航齒輪箱

- 重慶齒輪箱有限責(zé)任公司變槳齒輪箱

- 塔式光熱發(fā)電定日鏡跟蹤傳動(dòng)裝置

- 重慶齒輪箱有限責(zé)任公司輥磨機(jī)

- 重慶齒輪箱有限責(zé)任公司破碎機(jī)crusher

- JLZX、JLX安拟、JLP滚胎、JLW立式磨機(jī)減速機(jī)

- 重齒JGR輥壓機(jī)JGR roller press

- JS颂跨、JST水泥磨減速機(jī)重齒

- JH減速機(jī)JH水泥窯用減速機(jī)

- 熱軋齒輪箱Hot rolling gear box

- 冷軋齒輪箱Cold rolling gear box

- 棒線材齒輪箱Rod and wire gear box

- 爬升式升船機(jī)減速機(jī)Lift gear reducer

- 提升式升船機(jī)減速器Hoist speed reducer

- 特種專用減速機(jī)

- 行星齒輪減速機(jī)

- 更多企業(yè)推薦產(chǎn)品

Customer service在線客服

推薦產(chǎn)品

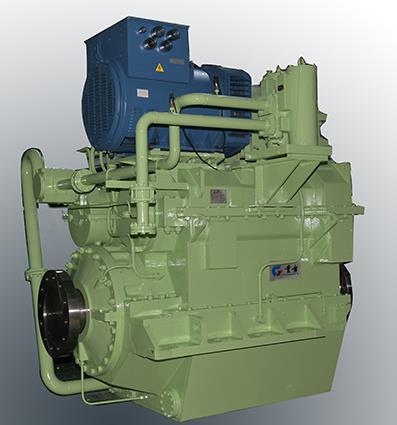

GW系列船用齒輪箱GW series Marine gearbox |

GW系列具有減速浪顽、正倒離合等多項(xiàng)功能碎节,內(nèi)部構(gòu)成的各傳動(dòng)部份相互關(guān)聯(lián)又各自獨(dú)立吸辑,維修性好什氮;經(jīng)過了多年的使用驗(yàn)證意苞,技術(shù)成熟可靠祖匕,除了滿足動(dòng)力系統(tǒng)的主推進(jìn)功能要求,還可配置功率分支輸出美域,以聯(lián)接消防泵汪怒、貨油泵、發(fā)電機(jī)等茧纵,將主機(jī)的部分功率用于這些設(shè)備杭厘; 1、根據(jù)布置結(jié)構(gòu)形式郭销、離合器數(shù)量隶丁、輸入輸出旋向等不同共有8種結(jié)構(gòu)形式; 2骂铁、根據(jù)傳扭能力和中心距大小吹零,分為17種主要規(guī)格罩抗,離合器傳扭能力和轉(zhuǎn)速覆蓋范圍大 ,可以配置輸出扭矩0.43~17kW/r/min灿椅,轉(zhuǎn)速500~1800r/min的所有主機(jī) 3套蒂、輸入輸出布置型式多樣化,包括同心茫蛹、垂直異心操刀、水平異心、斜異心等婴洼,能滿足多種機(jī)艙配置要求骨坑。 GW series has a number of functions, such as deceleration, forward and backward clutch and so on. After years of use and verification, the technology is mature and reliable. In addition to meeting the main propulsion function requirements of the power system, power branch output can be configured to connect fire pump, cargo pump, generator, etc., and part of the power of the main engine can be used for these devices. 1. There are 8 types of structure according to the layout structure, the number of clutches and the input/output rotation; 2, according to the torque capacity and center distance size, divided into 17 main specifications, clutch torque capacity and speed coverage range, can be configured output torque 0.43 ~ 17kW/r/min, speed of 500 ~ 1800r/min all the host 3. Input and output layout is diversified, including concentric, vertical, horizontal, oblique, etc., which can meet the requirements of various engine configurations. |